Industries - On a successful track with metal replacement

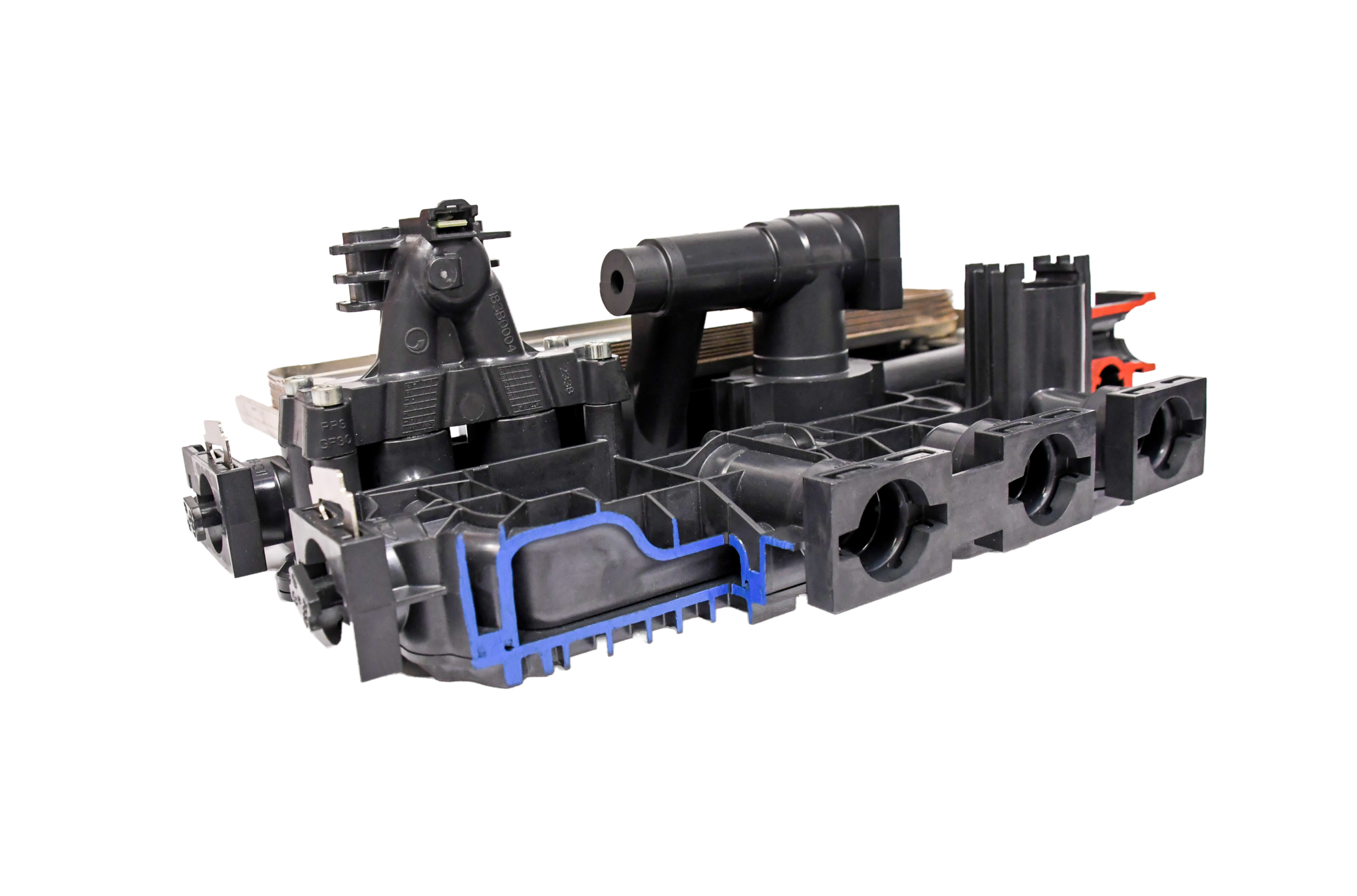

Metal replacement - we do it with great passion and our customers love it: replacing expensive, heavy, CO2-intensive and often functionally poor metal components with highly resilient components made from engineering thermoplastics. They are characterised by low weight, design freedom, great potential for functional integration and, last but not least, sustainability. The interplay of our material development, design expertise, design know-how and exciting manufacturing processes for injection moulding and joining components is what sets us apart.

Focus on building technology and fluid systems

At home in building services. Heating, exhaust gas routing, fresh water, hot water preparation, hydrogen, flowmeters... all applications in building technology with the highest demands on safety, operational stability and service life. GEALAN's material know-how, design expertise and process technologies make cost-efficient polymer applications with high functional integration possible.

Fluid Engineering

We have invested in our own versatile "Xbody" test specimen, installed a water laboratory and developed a special ageing process. We know the degradation of the decisive materials and thus the characteristic values for the realistic FEM simulation (finite element calculation). We go to the limit - see for yourself!

Heating

Hardly any other industry is subject to such major changes. Political framework conditions and global climate targets are setting the pace. The heat pump and economies of scale are presenting the market with huge challenges. With the development and validation of the right thermoplastic materials, expertise in component design and our complex manufacturing and joining processes, we are well positioned. We love complex components with high demands on operational stability and service life.

Hot water preparation

Whether as part of the heating system or as a stand-alone functional assembly - our fluid engineering expertise is also in demand here. Durable and high-pressure-resistant applications with a high degree of functional integration need to be developed and industrialised. Material expertise and complex tool design play an important role here. Innovative strength and the will to change are always decisive driving forces.

Greentech

Climate, environment, water and energy are the issues of the future more than ever. Hydrogen also has the potential to play a major role in the energy transition. GEALAN's fluid engineering expertise is also making a decisive contribution to the development of new applications in promising markets.

Connecting technology

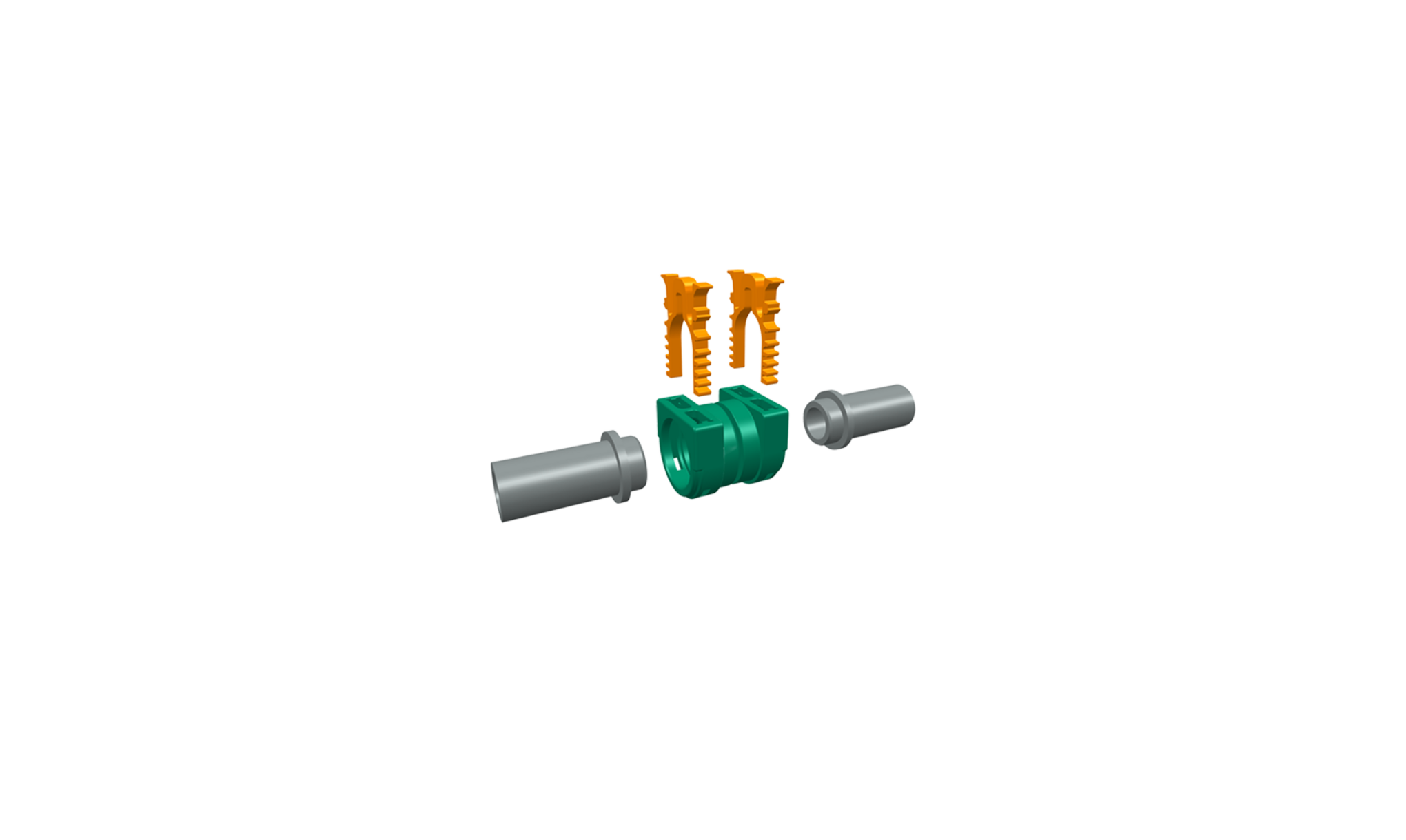

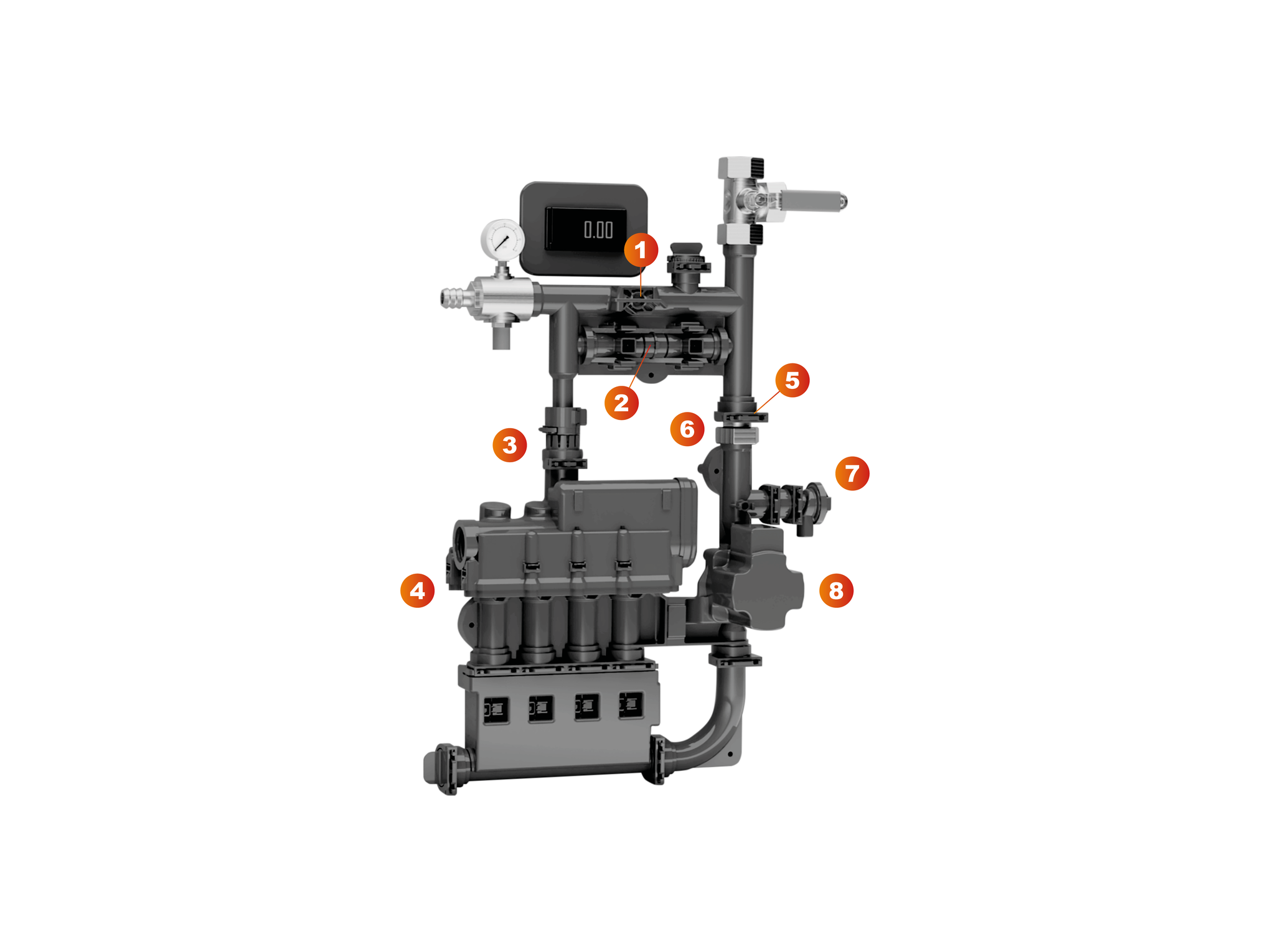

Everywhere in media-carrying and pressurised applications, system tightness in all operating conditions is a basic requirement. Suitable joining processes, expertise in sealing systems and design as well as imaginative joining techniques help us to inspire our customers. "Xtorque" - our innovative connecting element with integrated overtorque protection with torque limitation or "Xlock360" - the ingenious plastic clamp with 360 degree grip for even and stress-reducing force distribution are examples of this.

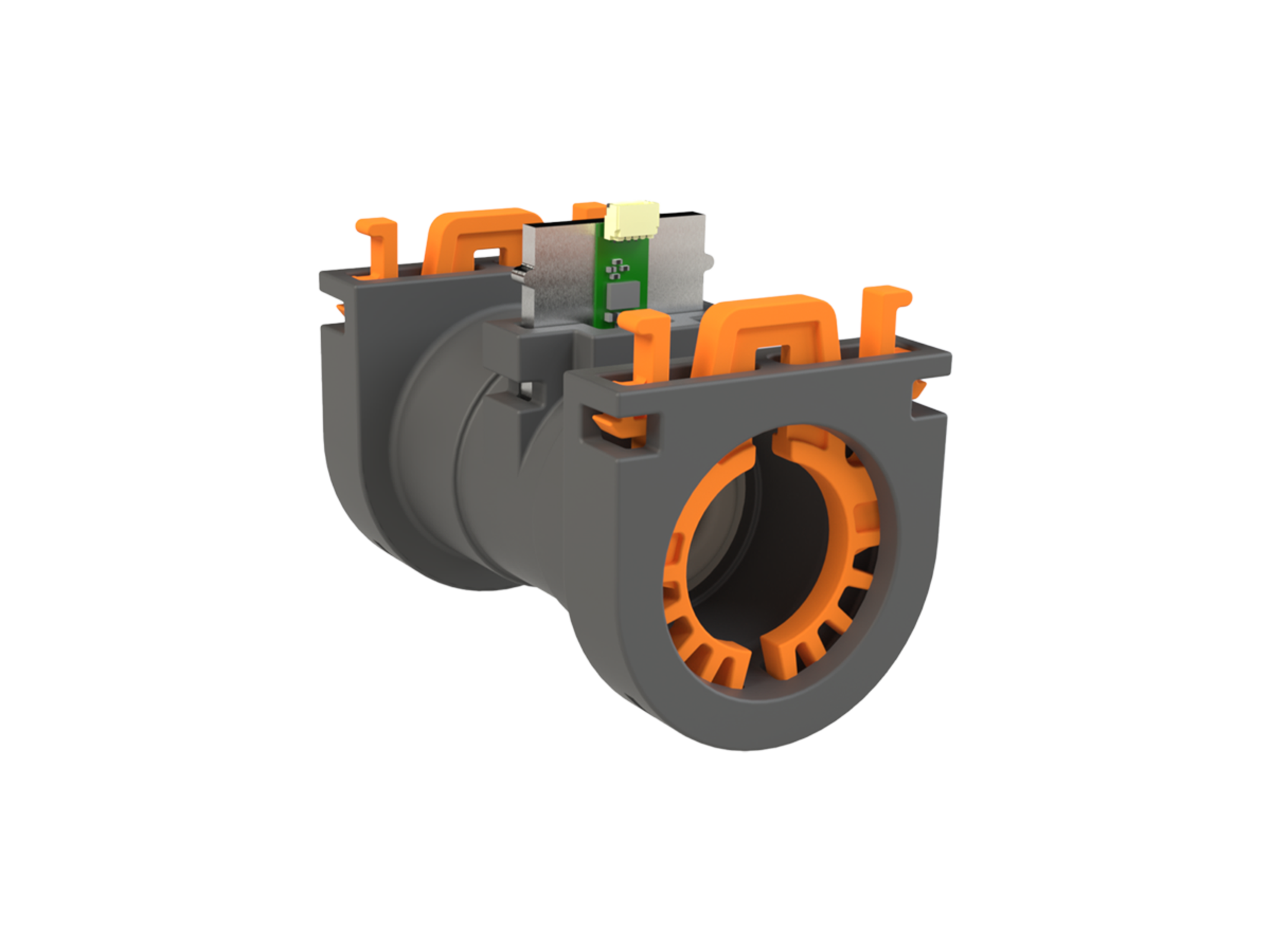

Differential pressure sensor technology

Combining expertise is the way forward. Together with a specialist in electronics and sensor technology, we have developed a differential pressure sensor that combines precision polymer technology with state-of-the-art microelectronics.

Perfect for demanding fluid applications, this sensor delivers accurate measurements without compromising on compactness or durability.

Polymer & valve technology

Benefit from combined expertise in fluid engineering. Together with RAPA, a valve technology expert based in Selb, Germany, we develop high-performance fluid solutions. We combine innovative polymer and valve technology in an intelligent overall system, bringing together the potential of metal substitution, connection technology and valve & sensor technology.

Combined expertise for your applications!

Legend:

1) Calorimetric flow sensor

2) Differential pressure sensor

3) Xtorque – screw connection with torque limiter

4) 5-way proportional valve

5) Xlock360 – Tool-free pipe connection

6) Metal substitution/hybrid component

7) Safety valve + Xstopper

8) Direct integration of circulation pump