From design to the finished component

Individual customer requirements mean individual processes! We tailor our production processes to the needs of our customers. We are open to all technologies. From classic injection moulding, welding and foaming to finishing and assembly, we implement the specific requirements of our customers.

1-component injection moulding

In 1-component injection moulding, the selected plastic is melted and injected into the injection mould under high pressure. We use this process to produce technically sophisticated parts with a maximum unit weight of 6.4 kg on machines with clamping forces of up to 24,000 kN.

2-component injection moulding

In 2-component injection moulding, two materials are processed in a single step and joined with a material or form-fit. The material combinations are diverse. Production takes place on machines with a clamping force of up to 5,500 kN with index, rotary disc and locking slide moulds.

TFI - Thermoplastic foam injection

Thermoplastic foam moulding stands for lightweight construction and technical performance. The chemical or physical (MuCell) expansion of the components creates a foam structure in the core of the components. Weight reduction, warpage minimisation and dimensional stability are the most important assets of this innovative injection moulding process.

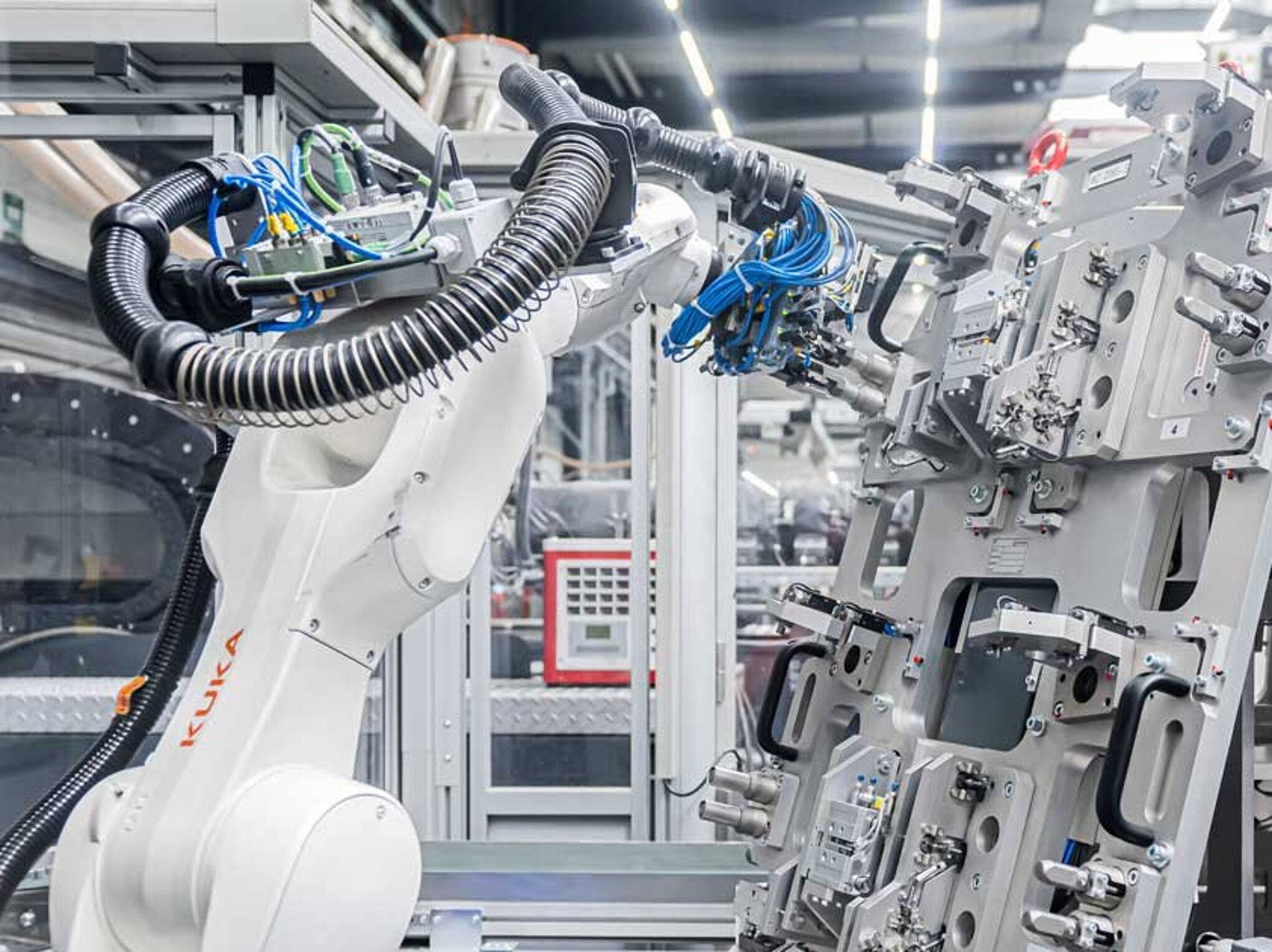

Inlay technology

Inserts can be inserted into the injection mould manually, semi-automatically or fully automatically. The insert is then overmoulded.

Polymer welding

Vibration welding, rotation welding, ultrasonic welding, mirror welding and laser welding - these are the joining processes we currently use to produce complex, pressure-resistant and function-integrating components.

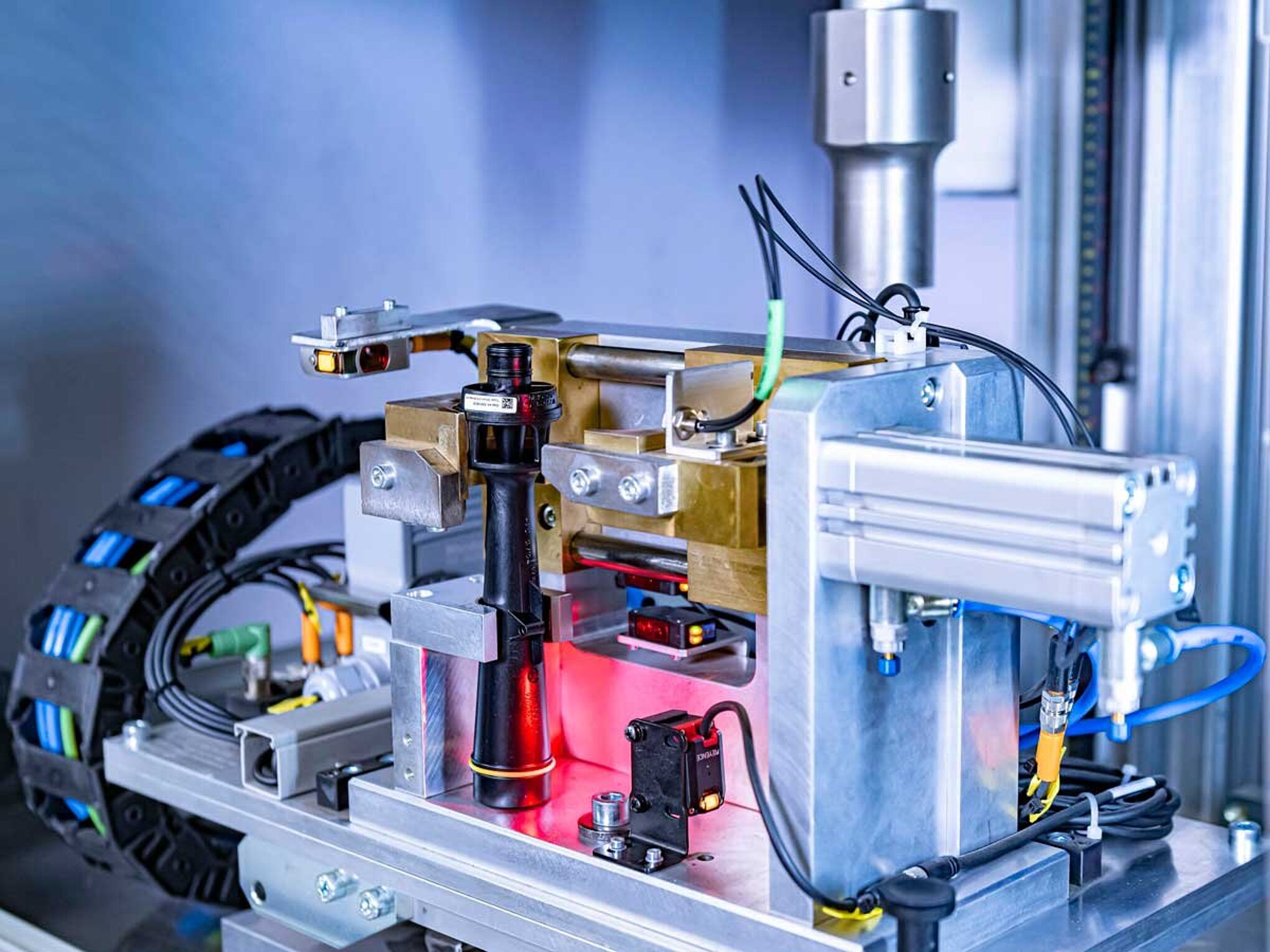

PUR foaming

PUR foaming enables us to apply seals with the optimum height directly to the 3D contour of the component. We can apply several seals in one work step. We use thixotropic and liquid PUR systems as well as patented Xgea speed foams with optimised height/width ratios and a very fast reaction time.

Assembly

We offer manual and fully automated assembly concepts including monitoring of required customer parameters and end-of-line testing.